Preparing for the Automotive Service Excellence (ASE) A2 – Auto Transmission / Transaxle exam and don’t know where to start?

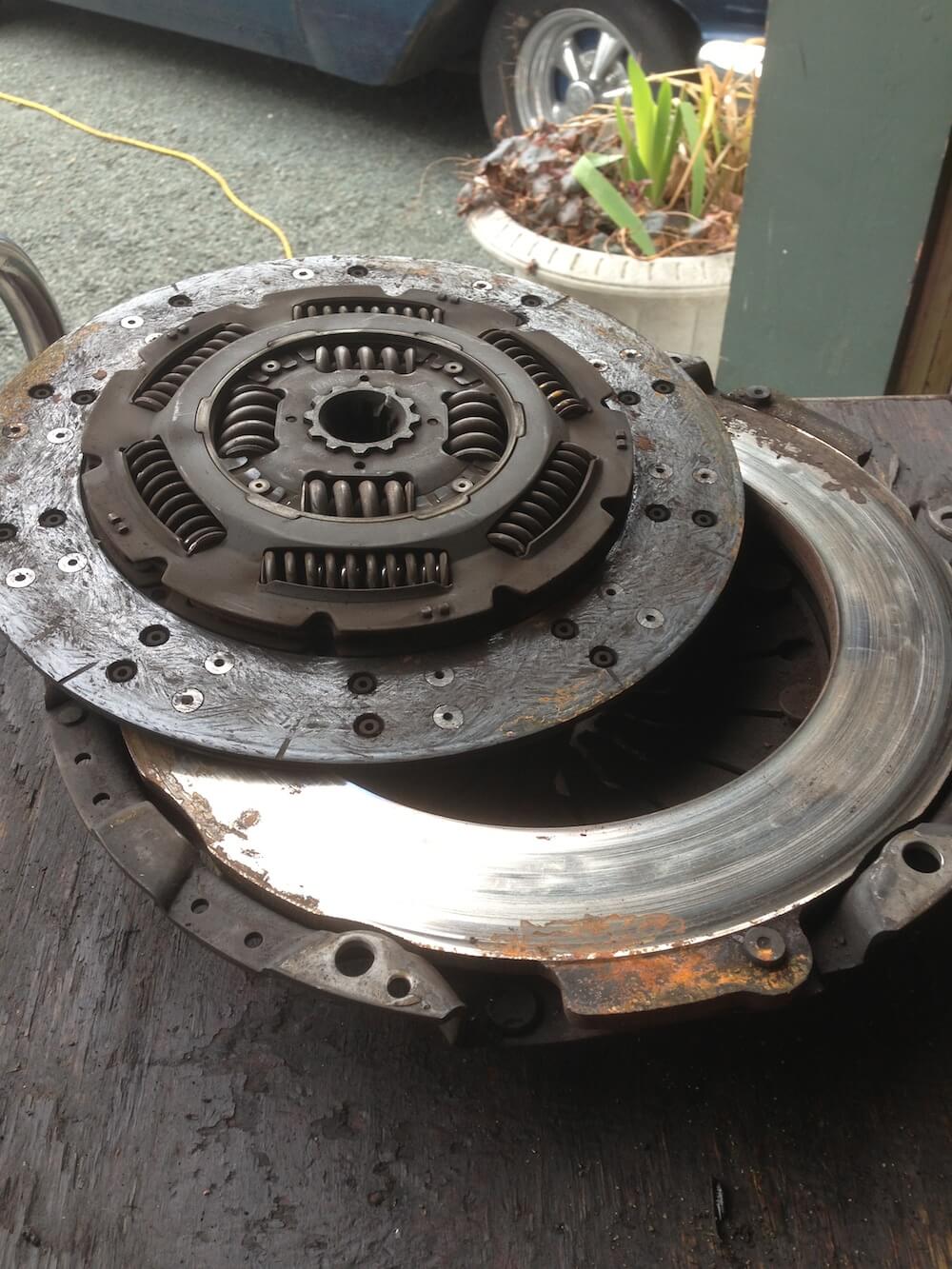

- Ford Clutch Assembly Diagrams

- Training Videos : Clutch Assembly The Mechanic Machine

- Training Videos : Clutch Assembly The Mechanical

Training center classes. The video library offers an extensive collection of videotapes to supplement your organization’s safety and health training program. It is a convenient and popular source for Ohio employers to borrow quality occupational safety- and h ealth-related training aids. Visit our Web site at www.ohiobwc.com. Central Library. DIY Mop-Up The son of a long-time customer called to tell us the floor shifter on his 1996 Pontiac Grand Am was stuck in Park. He also said the ERLS fuse blew every time he started the car. And, by the way, a replacement alternator was on the back seat of the car. By submitting this form, I agree that Universal Technical Institute, Inc., Custom Training Group, Inc., and their representatives may email, call, and / or text me with marketing messages about educational programs and services, as well as for school - related communications, at any phone number I provide, including a wireless number, using prerecorded calls or automated technology.

Topics for the A2 test include:

- General Transmission/Transaxle Diagnosis (Mechanical/Hydraulic Systems, Electronic Systems)

- In-Vehicle Transmission/Transaxle Maintenance and Repair

- Off-Vehicle Transmission/Transaxle Repair (Removal and Installation, Disassembly and Assembly, Friction and Reaction Units)

Test your knowledge with some free ASE tests and know where you stand! After clicking on your answer, be sure to review what the correct answer and explanation.

By using these free ASE test questions, you’ll know where to brush up on your automatic transmission and transaxle knowledge and exactly which study guides to hone in on and follow. Be sure to check out the auto mechanic certification requirements by state for additional information!

Good luck!

How did you do? Be sure to check out the rest of the free A1-A8 Certification test questions!

Pages: 12345678910

- 1915

- Part Number Title:Occup. Safety and Health Standards for Shipyard Employment

- 1915 Subpart Z

- Subpart Title:Toxic and Hazardous Substances

- Title:Work practices and engineering controls for automotive brake and clutch inspection, disassembly, repair and assembly - Mandatory

This mandatory appendix specifies engineering controls and work practices that must be implemented by the employer during automotive brake and clutch inspection, disassembly, repair, and assembly operations. Proper use of these engineering controls and work practices by trained employees will reduce employees' asbestos exposure below the permissible exposure level during clutch and brake inspection, disassembly, repair, and assembly operations. The employer shall institute engineering controls and work practices using either the method set forth in paragraph [A] or paragraph [B] of this appendix, or any other method which the employer can demonstrate to be equivalent in terms of reducing employee exposure to asbestos as defined and which meets the requirements described in paragraph [C] of this appendix, for those facilities in which no more than 5 pairs of brakes or 5 clutches are inspected, disassembled, reassembled and/or repaired per week, the method set forth in paragraph [D] of this appendix may be used:

[A] Negative Pressure Enclosure/HEPA Vacuum System Method

(1) The brake and clutch inspection, disassembly, repair, and assembly operations shall be enclosed to cover and contain the clutch or brake assembly and to prevent the release of asbestos fibers into the worker's breathing zone.

(2) The enclosure shall be sealed tightly and thoroughly inspected for leaks before work begins on brake and clutch inspection, disassembly, repair, and assembly.

(3) The enclosure shall be such that the worker can clearly see the operation and shall provide impermeable sleeves through which the worker can handle the brake and clutch inspection, disassembly, repair and assembly. The integrity of the sleeves and ports shall be examined before work begins.

(4) A HEPA-filtered vacuum shall be employed to maintain the enclosure under negative pressure throughout the operation. Compressed-air may be used to remove asbestos fibers or particles from the enclosure.

(5) The HEPA vacuum shall be used first to loosen the asbestos containing residue from the brake and clutch parts and then to evacuate the loosened asbestos containing material from the enclosure and capture the material in the vacuum filter.

(6) The vacuum's filter, when full, shall be first wetted with a fine mist of water, then removed and placed immediately in an impermeable container, labeled according to paragraph (k)(8) of this section and disposed of according to paragraph (l) of this section.

(7) Any spills or releases of asbestos containing waste material from inside of the enclosure or vacuum hose or vacuum filter shall be immediately cleaned up and disposed of according to paragraph (l) of this section.

[B] Low Pressure/Wet Cleaning Method

(1) A catch basin shall be placed under the brake assembly, positioned to avoid splashes and spills.

(2) The reservoir shall contain water containing an organic solvent or wetting agent. The flow of liquid shall be controlled such that the brake assembly is gently flooded to prevent the asbestos-containing brake dust from becoming airborne.

(3) The aqueous solution shall be allowed to flow between the brake drum and brake support before the drum is removed.

(4) After removing the brake drum, the wheel hub and back of the brake assembly shall be thoroughly wetted to suppress dust.

(5) The brake support plate, brake shoes and brake components used to attach the brake shoes shall be thoroughly washed before removing the old shoes.

(6) In systems using filters, the filters, when full, shall be first wetted with a fine mist of water, then removed and placed immediately in an impermeable container, labeled according to paragraph (k)(8) of this section and disposed of according to paragraph (l) of this section.

(7) Any spills of asbestos-containing aqueous solution or any asbestos-containing waste material shall be cleaned up immediately and disposed of according to paragraph (l) of this section.

(8) The use of dry brushing during low pressure/wet cleaning operations is prohibited.

[C] Equivalent Methods

An equivalent method is one which has sufficient written detail so that it can be reproduced and has been demonstrated that the exposures resulting from the equivalent method are equal to or less than the exposures which would result from the use of the method described in paragraph [A] of this appendix. For purposes of making this comparison, the employer shall assume that exposures resulting from the use of the method described in paragraph [A] of this appendix shall not exceed 0.016 f/cc, as measured by the OSHA reference method and as averaged over at least 18 personal samples.

[D] Wet Method

Ford Clutch Assembly Diagrams

(1) A spray bottle, hose nozzle, or other implement capable of delivering a fine mist of water or amended water or other delivery system capable of delivering water at low pressure, shall be used to first thoroughly wet the brake and clutch parts. Brake and clutch components shall then be wiped clean with a cloth.

(2) The cloth shall be placed in an impermeable container, labelled according to paragraph (k)(8) of this section and then disposed of according to paragraph (l) of this section, or the cloth shall be laundered in a way to prevent the release of asbestos fibers in excess of 0.1 fiber per cubic centimeter of air.

(3) Any spills of solvent or any asbestos containing waste material shall be cleaned up immediately according to paragraph (l) of this section.

Training Videos : Clutch Assembly The Mechanic Machine

(4) The use of dry brushing during the wet method operations is prohibited.

Training Videos : Clutch Assembly The Mechanical

[58 FR 35553, July 1, 1993; 59 FR 40964, Aug. 10, 1994; 60 FR 9624, Feb. 21, 1995; 60 FR 33343, June 28, 1995; 60 FR 33972, June 29, 1995; 60 FR 36043, July 13, 1995; 60 FR 50411, Sept. 29, 1995; 61 FR 5507, Feb. 13, 1996; 61 FR 43454, August 23, 1996]